In the realm of infrastructure maintenance, one often overlooked aspect is the durability and longevity of piping systems. Whether it’s for residential, commercial, or industrial purposes, pipelines form the lifelines of our built environment, facilitating the flow of water, gas, sewage, and various other substances crucial for daily operations. However, over time, these pipelines can deteriorate, leading to leaks, blockages, and structural weaknesses that can be both costly and hazardous. Traditional methods of repairing or sewer pipe relining can be disruptive, time-consuming, and expensive.

Enter pipe relining: a modern, innovative solution that offers significant advantages over conventional pipe repair methods. Pipe relining involves reinforcing or replacing damaged pipelines without the need for excavation or complete replacement. Instead, it utilizes trenchless technology to rehabilitate existing pipes from within, offering a cost-effective and efficient alternative for restoring the functionality and durability of piping systems.

Understanding Pipe Relining

Pipe relining employs advanced materials and techniques to rehabilitate pipelines while minimizing disruption to the surrounding environment. The process typically involves the following steps:

- Assessment and Inspection: The first step in pipe relining is to conduct a thorough inspection of the existing pipeline using CCTV cameras or similar equipment. This allows technicians to assess the extent of damage, identify any blockages or leaks, and determine the suitability of the pipe for relining.

- Preparation: Before relining can commence, the pipeline must be cleaned and prepared to ensure optimal adhesion of the lining material. High-pressure water jetting or mechanical cleaning tools are often used to remove debris, scale, and corrosion from the interior surface of the pipe.

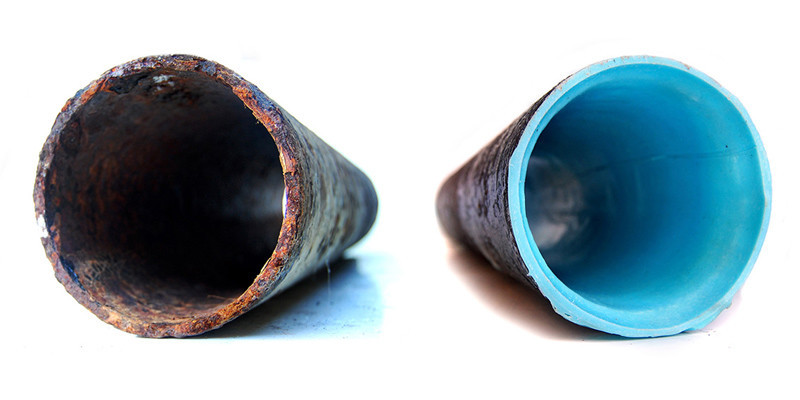

- Lining Installation: Once the pipeline is clean and prepared, the lining material is inserted into the pipe using specialized equipment. The lining material, typically a flexible resin or epoxy, is impregnated into a liner and inserted into the pipe. Using air pressure or inversion techniques, the liner is then inflated or inverted to conform to the shape of the pipe and bond with the existing surface.

- Curing and Solidification: After the liner is in place, it is cured or solidified using heat, UV light, or chemical processes. This ensures that the lining material hardens and forms a durable, watertight barrier within the existing pipe, effectively sealing any cracks, leaks, or structural defects.

- Quality Assurance: Once the lining has cured, a final inspection is conducted to ensure that the relined pipe meets industry standards and specifications. This may involve conducting pressure tests, flow assessments, or additional CCTV inspections to verify the integrity and performance of the rehabilitated pipeline.

Benefits of Pipe Relining

Pipe relining offers numerous benefits compared to traditional pipe repair or replacement methods:

- Cost-Effectiveness: By eliminating the need for excavation and minimizing labor and material costs, pipe relining can result in significant cost savings compared to conventional repair or replacement methods.

- Minimal Disruption: Since pipe relining is performed without excavation, it minimizes disruption to the surrounding environment, reduces traffic congestion, and eliminates the need for extensive restoration work.

- Faster Installation: Pipe relining can be completed in a fraction of the time required for traditional repair or replacement methods, allowing for quicker restoration of service and reduced downtime for businesses and residents.

- Long-Term Durability: The materials used in pipe relining are highly durable and resistant to corrosion, erosion, and chemical damage, ensuring long-term performance and reliability of the rehabilitated pipeline.

- Environmental Sustainability: Trenchless pipe relining produces minimal waste and environmental impact compared to excavation-based methods, making it a more sustainable and eco-friendly solution for pipeline rehabilitation.

Conclusion

In an age where infrastructure maintenance and sustainability are paramount concerns, pipe relining offers a forward-thinking solution for ensuring the long-term durability and functionality of piping systems.