In the world of manufacturing and engineering, finding solutions to design challenges is a constant pursuit. One technology that has been instrumental in overcoming many of these hurdles is A356 Aluminum Casting. This versatile process offers unique advantages that address a wide range of design complexities. In this blog, we’ll explore how aluminum casting serves as a powerful tool in solving design challenges.

The Power of Aluminum Casting

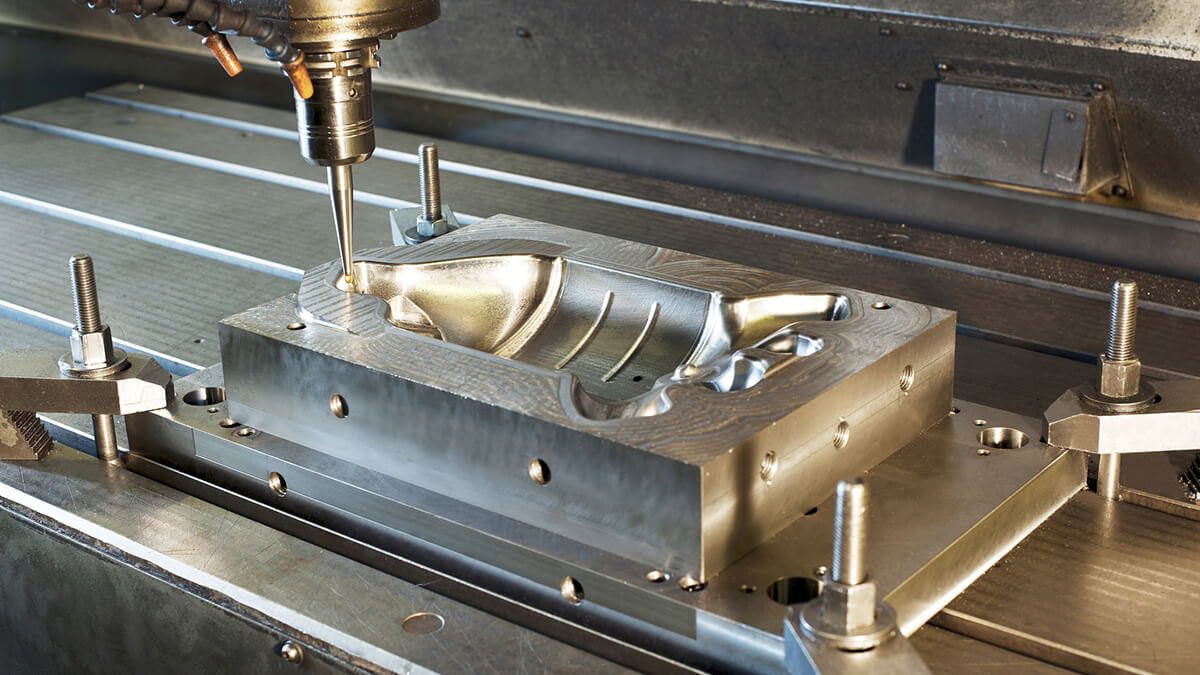

Aluminum casting is a manufacturing process that involves pouring molten aluminum into molds to create intricate and customized components. This method has gained popularity across industries for its ability to produce complex, high-quality parts with exceptional precision and detail. Let’s delve into how aluminum casting tackles various design challenges:

1. Complex Geometries

Designs that feature intricate shapes, undercuts, and fine details can be challenging to manufacture using traditional methods. Aluminum casting excels in this area, allowing for the production of components with complex geometries that would be nearly impossible to achieve with other techniques.

2. Weight Optimization

In industries where weight is a critical factor, such as aerospace and automotive, aluminum casting offers a significant advantage. It provides a high strength-to-weight ratio, allowing for the creation of lightweight yet durable parts. This is especially crucial for applications where reducing weight leads to improved efficiency and performance.

3. Corrosion Resistance

In environments where corrosion is a concern, such as marine or coastal applications, aluminum casting is a go-to solution. Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This property ensures that components remain robust and reliable, even in harsh conditions.

4. Material Efficiency

Aluminum casting is known for its material efficiency. Unlike subtractive manufacturing processes that involve cutting away excess material, casting uses only the amount needed to create the final component. This minimizes waste and helps optimize material usage, making it a more sustainable option.

5. Heat Dissipation

In applications where efficient heat dissipation is critical, aluminum’s excellent thermal conductivity comes into play. Components like heat sinks and engine parts benefit greatly from this property, ensuring optimal performance and longevity.

Industries Benefiting from Aluminum Casting

The versatility and effectiveness of aluminum casting have made it an invaluable tool in various industries. Here are some sectors where aluminum casting has proven instrumental:

1. Automotive

In the automotive industry, lightweighting is a major focus to enhance fuel efficiency and reduce emissions. Aluminum casting is widely used for producing engine components, transmission housings, and other critical parts.

2. Aerospace

Aerospace applications demand materials that are both lightweight and high-performing. Aluminum casting plays a pivotal role in producing components for aircraft and spacecraft, contributing to improved efficiency and safety.

3. Marine

The marine industry benefits from aluminum casting due to its corrosion resistance and lightweight properties. Components like hulls, propellers, and structural elements are commonly manufactured through this process.

4. Electronics

In the electronics industry, aluminum casting is crucial for producing components like heat sinks, which are vital for dissipating heat generated by electronic devices.

5. Construction

Aluminum casting finds application in architectural elements, structural components, and various fixtures used in construction. Its versatility allows for the creation of customized designs that meet specific project requirements.

Pushing Boundaries Through Innovation

As technology continues to advance, so too does the field of aluminum casting. Ongoing research and development are leading to the discovery of new alloys, improved casting techniques, and enhanced quality control processes. These innovations are expanding the capabilities of aluminum casting, enabling it to tackle even more intricate and demanding design challenges.

In Conclusion

Aluminum casting stands as a testament to the ingenuity and adaptability of modern manufacturing processes. Its ability to address complex design challenges across a range of industries has solidified its place as a cornerstone of engineering innovation. As we continue to push the boundaries of what’s possible, aluminum casting will undoubtedly play a pivotal role in shaping the future of manufacturing and design.